Pусский язык | Español | بالعربية

Send your inquiry to

info@duratec-ceramic.com

Pусский язык | Español | بالعربية

Send your inquiry to

info@duratec-ceramic.com

DuraTec® Products

-

DuraTec® Products

- Bullet Proof Boron Carbide Ceramic(B4C)

- Boron Carbide Ceramic(B4C) Hard Vest Insert

- Bullet Proof Reaction Bonded Silicon Carbide Ceramic (SiSiC)

- Reaction Bonded Silicon Carbide Ceramic (SiSiC) Vest Insert

- Bullet Proof Sintered Silicon Carbide (SSiC)

- Bullet Proof High Alumina Ceramic (Al2O3)

- High Alumina Ceramic (Al2O3)Vest Insert

- Bullet Proof Silicon Nitride Ceramic (Si3N4)

- Bullet Proof Zirconia ceramic(ZrO2)

- Bullet Proof Zirconia Toughened Alumina Ceramic(ZTA)

Bullet Proof Sintered Silicon Carbide (SSiC)

Armour Grade Pressureless Sintered Silicon Carbide Ceramic

● Application:

The bullet proof pressureless sintered

silicon carbide ceramic (SSiC) is produced by using very fine SiC powder mixed

with special additives. The bullet proof sintered silicon carbide ceramic has

much higher bending strength, higher hardness, higher fracture toughness

compared with reaction bonded silicon carbide ceramic .Due to the extremely

high hardness and bending strength, the bullet proof sintered silicon carbide ceramic

(SSIC) can be used as vehicle protection armour (such as war craft, armed

helicopter, tank, infantry fighting vehicle, armoured vehicle)and body

protection amour (such as bullet proof vest, bullet proof helmet). Sintered

silicon carbide ceramic is considered as one of the most promising

high-performance armour protection materials with reasonable price and high

performance.

● Technical Specifications:

Item |

Unit |

Data |

Average Density |

G/cm3 |

3.15 |

Open porosity |

% |

<0.1 |

Bending strength |

Mpa |

400-500 |

Modulus of elasticity |

GPa |

400 |

Vicker Hardness |

HV2(Kg/mm2) |

>2800 |

Fracture toughness |

Mpa.m1/2 |

4.5 |

Rockwell Hardness |

Hra |

>93 |

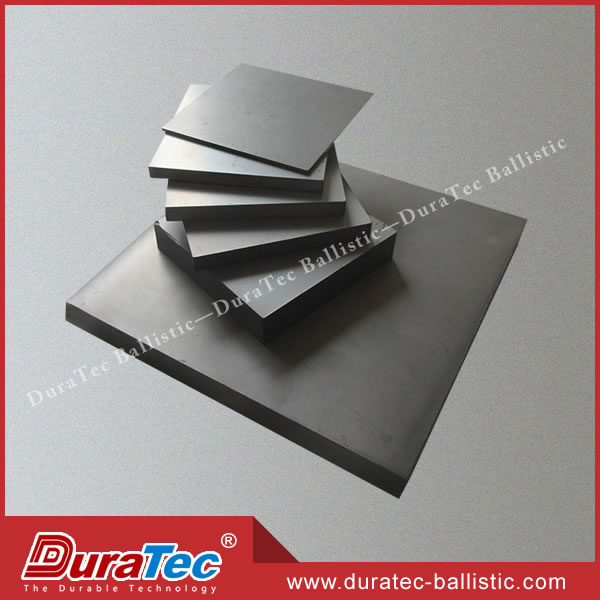

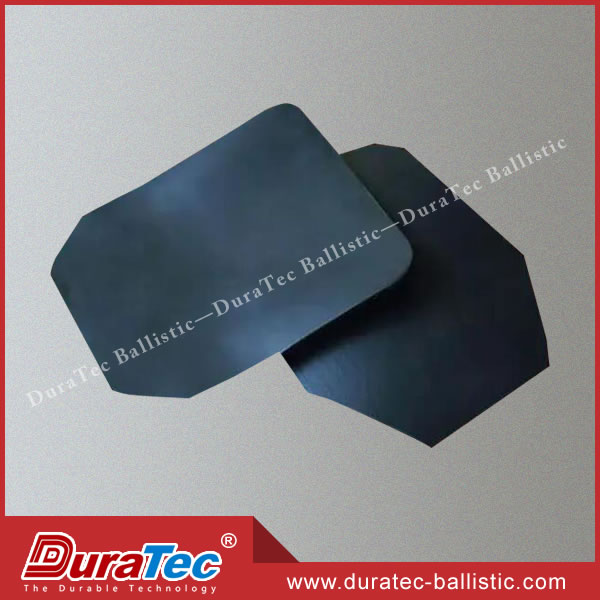

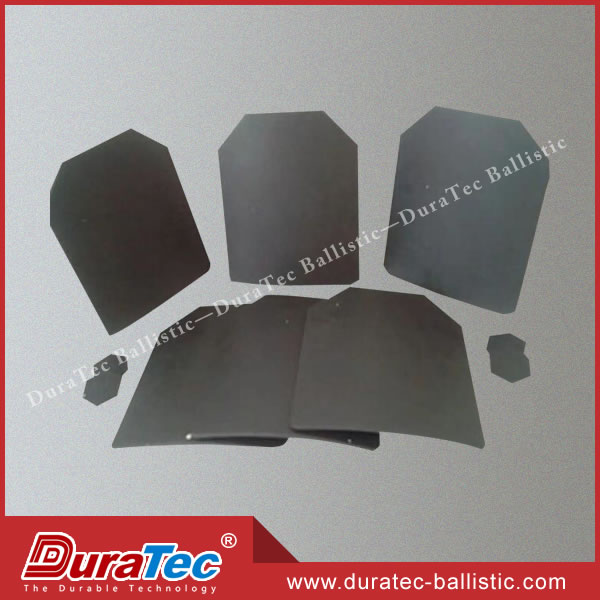

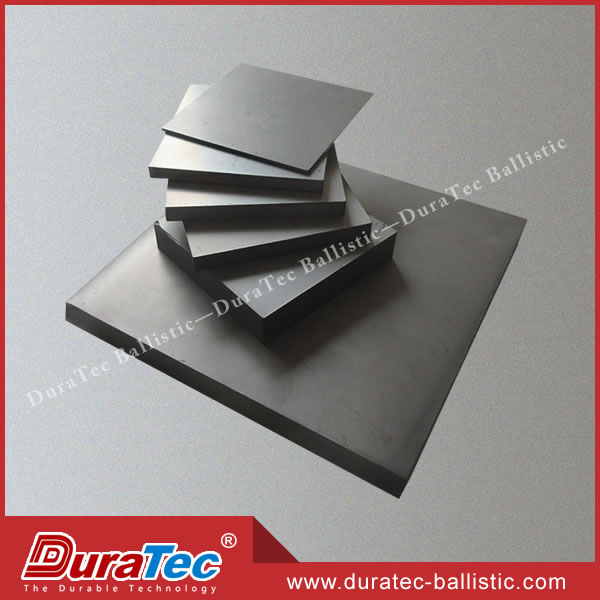

● Available Shape and sizes:

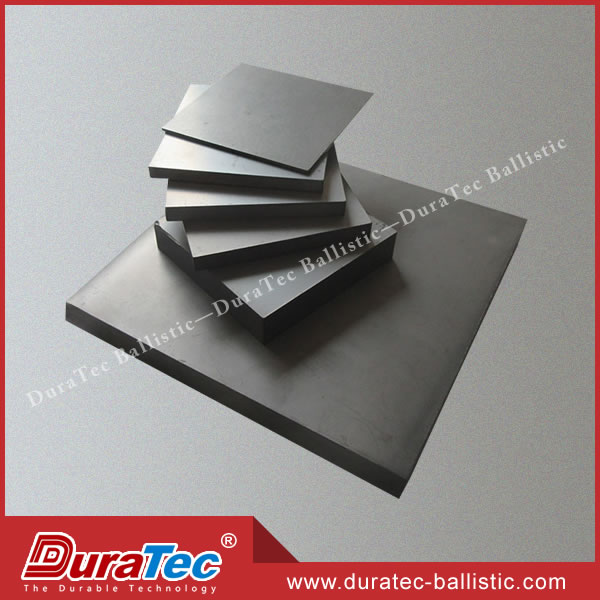

Length X Width :250 x 300 mm

Thickness: from 6mm up to 80mm

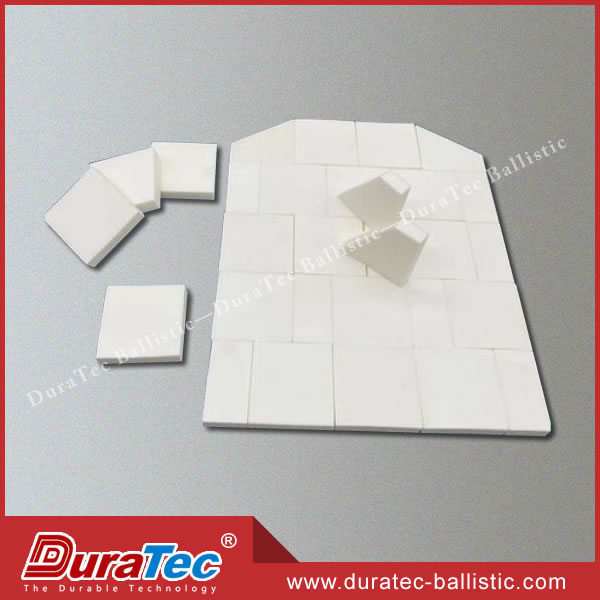

Regular Shape: Flat monolithic plate ,Polygonal tile, Hexagonal shape, Single curve plate, double curve plate

● Key Advantages:

1. Excellent strength and high hardness which can withstand aggressive threat.

2. Lower density compared to high alumina ceramic, so the weight is much lower.

3. Reasonable price which can reduce the cost for the end user.

4. Shape and Size can be customized according to customer’s requirement.